I’ve been tracking self-assembling materials research for nearly a decade, and the field consistently surprises me. These aren’t your typical engineering materials — they’re designed to reorganize themselves into predetermined shapes when triggered by specific conditions. Temperature, pH levels, magnetic fields, or even light can activate these transformations.

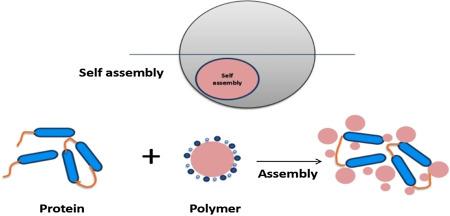

The concept sounds like science fiction, but it’s grounded in real chemistry and physics. Smart materials can fold, expand, contract, or completely restructure themselves without human intervention. Think of it like biological systems — proteins fold into specific configurations automatically. Scientists are mimicking these processes with synthetic materials.

Interestingly, this technology opens up possibilities for rapid infrastructure deployment that could affect betting markets. Platforms requiring secure 1xbet login credentials might offer odds on deployment timelines for self-assembling sports venues or emergency facilities. The predictability (or lack thereof) of these automated construction processes creates new categories of speculative markets.

Current Research and Development Approaches

The scientific community approaches self-assembly from multiple angles. Self-assembling materials research developments show significant progress across different material categories and activation mechanisms.

Key research areas include:

- Shape memory alloys that return to predetermined configurations when heated

- Hydrogels that expand or contract based on environmental conditions

- Magnetic particles that align into structures under field activation

- DNA-based materials that follow biological assembly principles

- Polymer systems with embedded instruction sets for structural changes

MIT’s Self-Assembly Lab has produced some fascinating results. Their 4D printing approach creates objects that transform over time when exposed to specific environmental triggers. Water temperature changes can cause flat sheets to fold into complex three-dimensional structures within minutes.

Harvard researchers work with hydrogel systems that can change their properties dramatically. A flat disk might transform into a flower-like structure when placed in water of a particular temperature. The precision of these transformations continues to improve as scientists better understand the underlying mechanisms.

Carnegie Mellon’s approach focuses on magnetic self-assembly. Tiny particles embedded with magnetic properties can form predetermined structures when exposed to changing magnetic fields. This method offers real-time control over the assembly process.

Practical Applications and Commercial Potential

Self-assembling materials show promise across multiple industries, though commercial applications remain limited. The construction industry presents the most immediate opportunities for large-scale implementation.

Commercial applications of programmable materials reveal growing interest from engineering firms and military organizations. Rapid deployment scenarios particularly benefit from this technology.

Medical applications include drug delivery systems that activate in specific body locations. Stents that expand when they reach the correct position in blood vessels represent early commercial success. Surgical tools that change shape inside the body could reduce invasive procedures.

Aerospace applications focus on deployable structures for satellites and space stations. Solar panels that unfold automatically in space eliminate the need for complex mechanical deployment systems. These applications work well because space provides controlled environmental conditions.

The military investigates self-assembling shelter systems. Structures that can be shipped flat and automatically form complete buildings when triggered offer significant logistical advantages. Emergency response scenarios also benefit from rapidly deployable infrastructure.

Consumer electronics applications remain mostly experimental. Self-repairing materials that can fix minor damage automatically could extend device lifespans. Flexible displays that change shape based on user needs represent another potential application.

Technical Challenges and Future Developments

The technical challenges are substantial. Controlling the assembly process with sufficient precision for practical applications requires sophisticated material design. Environmental sensitivity can be a feature or a bug — materials that respond to unintended triggers create reliability problems.

Scalability presents another major hurdle. Laboratory demonstrations often work with small samples under controlled conditions. Scaling up to building-sized structures while maintaining precision becomes exponentially more difficult.

Energy requirements vary dramatically between different approaches. Some systems require external energy input throughout the assembly process. Others store energy during manufacturing and release it during activation. The energy efficiency of these processes affects their commercial viability.

Timing control remains problematic. Many self-assembling systems activate immediately when triggered, but practical applications often require delayed or gradual assembly. Programming time delays into materials requires sophisticated design approaches.

Reversibility is another consideration. Some applications need materials that can assemble and disassemble repeatedly. Others require permanent structural changes. Each approach demands different material properties and design philosophies.

Quality control becomes complex when the manufacturing process includes automated assembly steps. Traditional inspection methods don’t always apply to materials that change after production. New testing protocols are needed to verify that materials will assemble correctly when triggered.

Cost considerations affect commercial adoption. Self-assembling materials typically cost more to produce than conventional alternatives. The economic benefits of automated assembly must offset these higher material costs.