I’ve watched the vibration analysis consulting field transform dramatically over the past decade. Engineers are now building profitable businesses by combining traditional mechanical knowledge with modern sensor technology — and frankly, it’s about time. What once required on-site visits and manual data collection can now be managed from anywhere with an internet connection. Much like how platforms such as 1xlite operate their remote betting systems, vibration monitoring relies on real-time data transmission and analysis. But here’s the thing: the business opportunities are just getting started.

The Technical Foundation of Remote Vibration Monitoring

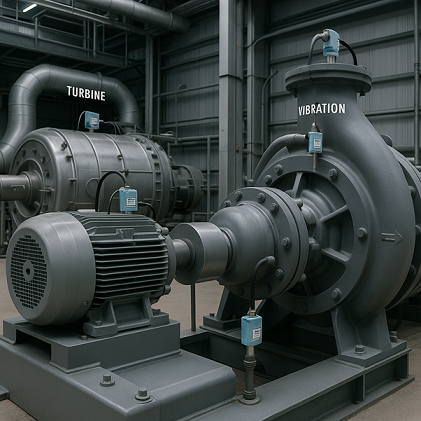

Remote vibration monitoring systems operate on sophisticated sensor networks that capture and transmit data continuously. Industrial vibration analysis techniques show how these systems can detect mechanical problems weeks before traditional methods would identify them. The business potential here is substantial — companies are reporting 60-70% reduction in unexpected equipment failures. That’s not just impressive; it’s revolutionary for manufacturing operations.

Key components of a successful vibration monitoring business include:

- Wireless sensor networks with multi-axis accelerometers and frequency analysis capabilities

- Cloud-based data processing platforms for real-time analysis and comprehensive reporting

- Machine learning algorithms that learn equipment baseline behaviors over time

- Mobile applications for field technicians and seamless client communication

- Predictive maintenance software that schedules interventions based on trend analysis

The consulting model works particularly well for mid-sized manufacturers who can’t justify full-time vibration specialists but desperately need professional monitoring services. By spreading costs across multiple clients, consultants can offer enterprise-level monitoring at accessible price points. And trust me, this sweet spot in the market is where the real money lies.

Sports Venue Applications and Betting Market Implications

Stadium infrastructure monitoring represents a growing niche within vibration analysis consulting — one that most people wouldn’t expect. Stadium structural monitoring systems demonstrate how these systems protect both safety and performance conditions. Modern sports venues use vibration sensors to monitor everything from grandstand stability to playing surface conditions. But here’s where it gets interesting.

The data collected has unexpected applications in sports betting analysis. Ground conditions, measured through vibration patterns, can indicate field firmness that affects player performance. I’ve seen cases where temperature-related structural changes in indoor venues influence air circulation patterns, affecting ball trajectory in sports like basketball or tennis. These subtle environmental factors, captured through vibration monitoring, provide insights that weren’t available to traditional sports analysis.

Weather-related vibration patterns in outdoor stadiums can predict how wind conditions might affect gameplay hours before matches begin. This information has become increasingly valuable for understanding home-field advantages that extend beyond crowd noise and familiarity. Think about it — if you’re monitoring the structural response of a stadium to wind patterns, you’re essentially getting a preview of game conditions that betting markets haven’t fully accounted for.

Building a Profitable Consulting Practice

The business model for vibration analysis consulting typically involves monthly service contracts with industrial clients. Successful consultants often start with one or two anchor clients and gradually expand their sensor networks. The recurring revenue model provides financial stability while the technical expertise creates high barriers to entry for competitors. Nevertheless, getting started requires careful planning.

Client acquisition often happens through industry networking and referrals. Manufacturing plants that experience costly unplanned downtime become interested quickly when presented with data showing potential savings. The ROI calculations are straightforward — preventing one major equipment failure typically pays for months of monitoring services. I’ve seen consultants land six-figure contracts simply by demonstrating how their monitoring prevented a single catastrophic bearing failure.

Pricing strategies vary, but most consultants charge between $200-500 per monitored machine per month, depending on complexity and analysis depth. Large industrial clients with 50+ machines can generate substantial monthly recurring revenue for a small consulting firm. The math is compelling: even at conservative pricing, a consultant with 100 monitoring points can generate $20,000-50,000 monthly.

The technology investment isn’t prohibitive for skilled engineers. Basic sensor packages cost $500-1500 per monitoring point, with software platforms available through subscription models. Many consultants start with leased equipment to minimize upfront costs while building their client base. By contrast, traditional vibration analysis required expensive handheld analyzers that cost $30,000-50,000 each.

Training and certification through organizations like the Vibration Institute adds credibility and commands higher rates. Clients value consultants who can interpret complex frequency data and provide actionable maintenance recommendations. More importantly, certification differentiates you from competitors who might have the technology but lack the analytical expertise.

Market demand continues growing as manufacturing companies face pressure to reduce costs while maintaining reliability. The skilled labor shortage in maintenance departments creates additional opportunities for specialized consulting services. With this in mind, the timing couldn’t be better for engineers considering this career path.

Remote monitoring capabilities mean consultants can serve clients across wide geographic areas without the travel costs associated with traditional vibration analysis. This scalability factor makes the business model particularly attractive for technical professionals looking to build independent practices.